Gear Heads Talk CNC Manufacturing Techniques

From the oldest to the newest, in this article, we’ll delve into all types of techniques used in the process of CNC machining. The invention of the CNC machines represents a quantum leap in the way we now use raw materials. All the benefits that once seemed contradictory are now being achieved with ease. Knowing the facts about CNC machining means knowing where the future is taking us in regard to the development of all sorts of industries.

Below we’ll go over a quick review of the three most important techniques used in this field.

Turning

The historical development of this process is simply fascinating. It all started with the first wheel device used in the late 60s of the 16th century and through the precision enhanced metal parts of 1970s and all the way to the multiple axes of today’s CNC machines of the most prestigious precision engineering services. The ability to determine the right variables for each material is one of the few hardships that we no longer have to bother with – the right parameters can now be fed into the system and this has resulted in complete control – something that cannot be achieved without the help of connecting an information fed computer to a machine.

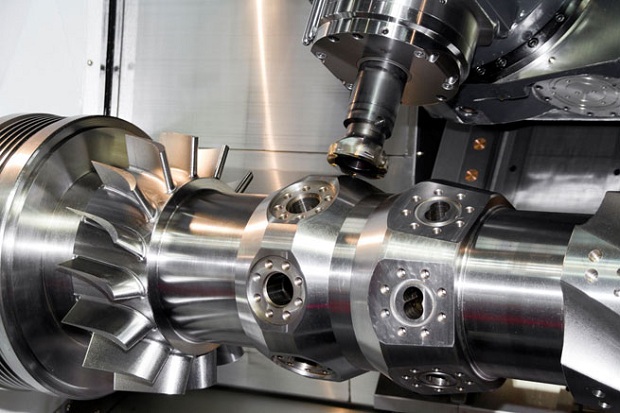

Milling

The adversary of turning in the world of machining – the one and only purpose is to hold the piece in place. The piece that has to be altered must be in a stationary position. This is true for all kinds of symmetrical or asymmetrical forms, although some are harder to keep in place than others and certain adjustments must be made. The horizontal table on which the piece will be paced is a must, along with the spindle that moves up and down and creates the desired effect of boring or drilling.

Surface Grinding

This technique serves the purpose of creating flat surface on metal parts – and this is what brings CNC machining as close to art as it gets. The notorious spinning disk, along with its abrasive cover is mounted on a table for the purpose of moving back and forth in a lateral manner. Looking back in history, nothing much has changed when it comes to this technique – it is still the best way known to man and the first thing that comes to mind regarding the creation of smooth and flat surfaces – which are much in demand in the field of precision engineering services.