A Comprehensive Guide to Auto Heat Shield Material: Protecting Your Vehicle from Heat Damage

When it comes to safeguarding your vehicle from excessive heat, the right auto heat shield material is indispensable. Whether you’re driving a high-performance sports car or a reliable family sedan, managing heat effectively is crucial for maintaining vehicle performance and preventing costly damage. But what exactly is auto heat shield material, and why is it so important?

Let’s talk about the various types of heat shield materials available, their applications, and how they contribute to the overall health of your vehicle.

What is Auto Heat Shield Material?

Auto heat shield material is designed to protect various parts of a vehicle from the intense heat generated by the engine, exhaust system, and other high-temperature components. It acts as a barrier, reflecting or dissipating heat away from critical areas, ensuring that sensitive parts like the fuel system, electronics, and interiors remain unaffected by extreme temperatures.

These materials come in different forms, including sheets, wraps, and pre-shaped shields, making them versatile for a range of applications. The right choice of heat shield material can enhance vehicle performance, prevent heat-related damage, and improve overall safety.

Why is Heat Management Important?

Modern vehicles are built for efficiency, and as engines become more powerful, they also generate more heat. Uncontrolled heat can lead to several issues:

- Component Failure: Excessive heat can cause parts like wiring, hoses, and gaskets to degrade prematurely. Over time, this can lead to malfunctions and costly repairs.

- Reduced Performance: High temperatures can impact the performance of various systems, such as the fuel and air intake systems. This can result in reduced horsepower and fuel efficiency.

- Safety Risks: In extreme cases, excessive heat can cause fires, especially if it affects fuel lines or flammable materials.

Managing heat effectively is therefore not just about maintaining performance but also ensuring the safety and longevity of your vehicle.

Types of Auto Heat Shield Materials

Choosing the right heat shield material depends on the specific needs of your vehicle. Here are some of the most commonly used materials and their applications:

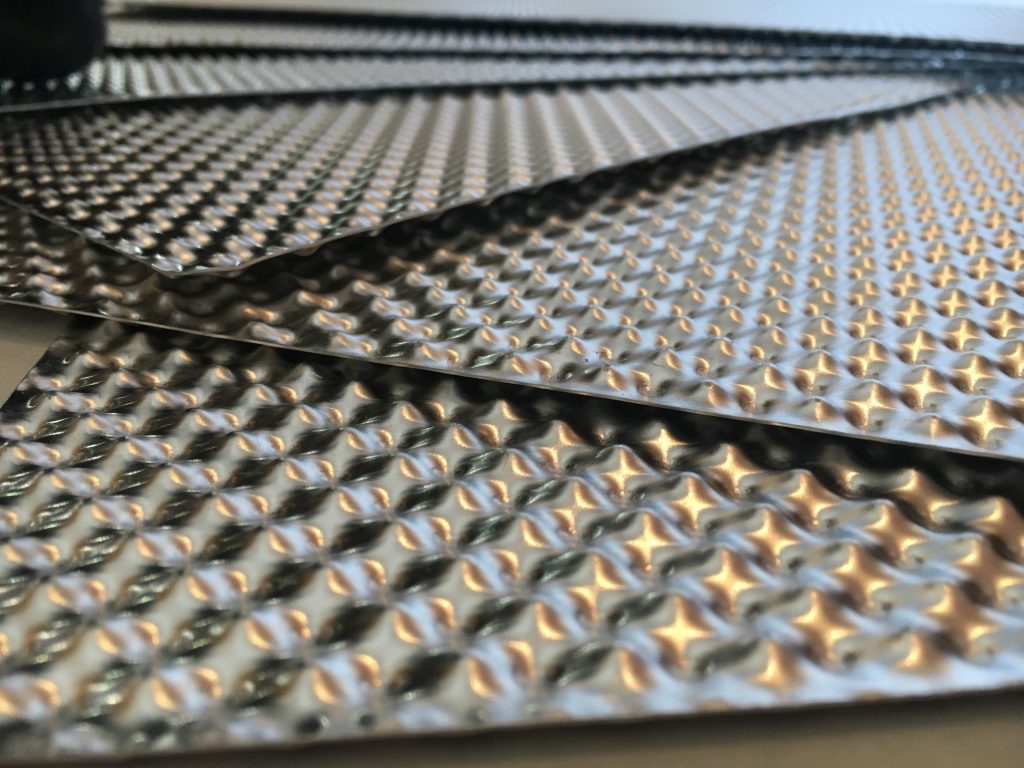

- Aluminium Heat Shields: Aluminium is a popular choice for heat shields due to its high reflectivity and lightweight nature. It’s often used in engine bays and exhaust systems to protect components from radiant heat. Aluminium shields are effective in reducing heat transfer and are relatively easy to install.

- Fibreglass Heat Shields: These are typically coated with a reflective aluminium layer. Fibreglass heat shields can withstand extremely high temperatures, making them ideal for use near exhaust manifolds, turbochargers, and downpipes. They are flexible and can be wrapped around components, providing excellent coverage.

- Ceramic-Based Heat Shields: Ceramic materials are known for their high thermal resistance. Ceramic-coated fabrics or composites are often used in high-performance vehicles and racing applications. They offer exceptional protection against both radiant and conductive heat.

- Stainless Steel Heat Shields: While heavier than aluminium, stainless steel offers superior durability and resistance to corrosion. It’s commonly used in areas exposed to high temperatures and harsh conditions, such as underbody shields and exhaust system protection.

- Thermal Wraps and Tapes: These are used to wrap around exhaust pipes and manifolds, helping to retain heat within the system, which can improve exhaust gas velocity and performance. They also prevent heat from radiating to nearby components.

Choosing the Right Heat Shield Material

Selecting the right heat shield material for your vehicle involves considering several factors:

- Application Area: Determine where the heat shield will be used. Engine bays, exhaust systems, and underbody areas all have different heat management needs.

- Temperature Range: Choose a material that can withstand the maximum temperatures in the area of application. For example, turbochargers and exhaust manifolds can reach temperatures of over 1000°C, requiring specialised materials.

- Durability and Resistance: Consider the environmental conditions the material will be exposed to. Materials like stainless steel are more suitable for areas prone to moisture and debris, while aluminium is ideal for areas needing lightweight protection.

- Ease of Installation: Some materials are easier to cut, shape, and install than others. Fibreglass and aluminium sheets are generally more user-friendly for DIY installations.

Benefits of Using Quality Heat Shield Material

Investing in high-quality heat shield material can provide numerous benefits, including:

- Enhanced Performance: By managing heat effectively, these materials can help maintain optimal operating conditions for various systems, resulting in improved performance and fuel efficiency.

- Increased Longevity: Protecting components from excessive heat prevents premature wear and tear, reducing the likelihood of breakdowns and extending the lifespan of your vehicle.

- Improved Comfort: Heat shields can also contribute to a more comfortable driving experience by reducing the amount of heat that enters the cabin, especially in high-performance or modified vehicles.

- Cost Savings: Preventing heat-related damage can save you from expensive repairs in the long run, making heat shield materials a smart investment for any vehicle owner.

Installing Auto Heat Shield Material

Proper installation is key to getting the most out of your heat shield material. Here are a few tips to ensure effective application:

- Plan Ahead: Identify the areas that need protection and measure them carefully to ensure you purchase the right amount of material.

- Prepare the Surface: Clean the surface where the heat shield will be applied to ensure good adhesion, especially for self-adhesive materials.

- Cut and Fit: Cut the material to size, allowing for any necessary folds or overlaps. Use heat-resistant gloves when handling materials like fibreglass.

- Secure the Material: Use appropriate fasteners or adhesives to secure the material in place. Ensure there are no gaps where heat could escape.

Conclusion

Auto heat shield materials are an essential part of any vehicle’s heat management system, protecting components from damage and ensuring optimal performance. Whether you’re looking to upgrade your existing setup or equip a high-performance vehicle, choosing the right heat shield material is crucial. With options ranging from aluminium to ceramic, there’s a solution for every application. By understanding the types and benefits of heat shield materials, you can make an informed choice that keeps your vehicle running safely and efficiently for years to come.